American Plastics LLC Midland: Selecting Pipes That Stand the Test of Time

Wiki Article

Locate the Perfect Pipe Supplies for every single Application in Your Market

Choosing the best pipeline materials is an important task for any kind of market. Different materials offer unique objectives, and the option can significantly influence effectiveness and security. It requires mindful consideration of variables like size, application demands, and compliance with guidelines. Understanding these components will assist professionals in making educated decisions. As they navigate these intricacies, the question stays: exactly how can one guarantee they are selecting the ideal options offered?Recognizing Different Pipeline Materials

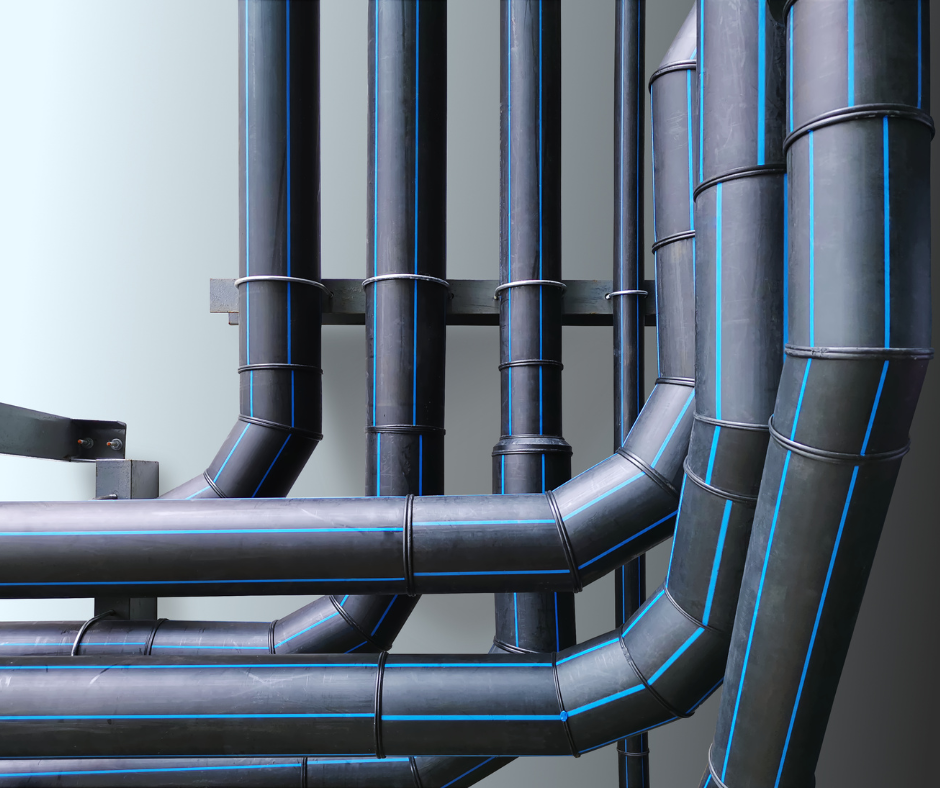

When choosing pipeline supplies for different applications, recognizing the distinctions among pipeline materials is important. Each kind of pipeline product offers special properties and benefits fit for details usages. PVC pipelines are light-weight, corrosion-resistant, and affordable, making them suitable for household pipes and irrigation systems. On the other hand, CPVC pipelines can stand up to greater temperature levels, making them ideal for warm water applications.Steel pipelines, such as copper and galvanized steel, are recognized for their longevity and stamina, often used in industrial setups. Copper is additionally immune to rust and has anti-bacterial residential or commercial properties. In contrast, steel pipes are preferred for their effectiveness in high-pressure systems. In addition, polyethylene pipelines are flexible and immune to chemicals, typically used in gas and water distribution. Inevitably, the choice of pipeline product substantially influences the effectiveness, longevity, and safety of the intended application, necessitating mindful consideration by industry specialists.

Examining Size and Specifications

Selecting the ideal dimension and specifications for pipeline materials is important for guaranteeing perfect performance in any type of application. The wall surface, size, and size density of pipelines straight influence their capability to handle liquid flow and pressure. It is essential to match these dimensions to the demands of the system in which they will certainly be used. Standard sizes are often offered, however customized requirements may be needed for specialized applications.In addition, the specifications should consist of factors to consider such as product compatibility, temperature tolerance, and stress ratings. These elements aid assure and avoid failings longevity. Correctly reviewing dimension and specifications not only improves functional performance but likewise lessens costs connected with product waste and system downtime.

Inevitably, a complete understanding of the essential dimension and specs allows sectors to make informed choices, leading to successful installations and trusted efficiency in their corresponding applications.

Evaluating Application Requirements

How can one assure that pipeline supplies meet the specific needs of an application? The very first step entails a thorough understanding of the functional setting (American Plastics LLC HDPE Pipe Supplier). Variables such as temperature fluctuations, stress levels, and exposure to corrosive materials should be carefully considered. Next off, the desired use of the pipes plays a vital function; whether they are suggested for delivering gases, solids, or liquids can considerably affect product selectionIn addition, the compatibility of pipeline products with the fluids being moved is crucial to ensure longevity and efficiency. It is additionally a good idea to speak with sector requirements and regulations that may determine particular requirements for products and construction methods. Seeking input from experienced experts in the area can provide useful insights. By rigorously reviewing these application requirements, one can with confidence pick pipe supplies that not only fit yet excel in their intended roles, improving efficiency and integrity in procedures.

Thinking About Expense and Schedule

Cost and availability are critical elements that affect the option of pipeline supplies for any application. Businesses should assess their budgetary restrictions while guaranteeing they have accessibility to the required products (American Plastics LLC). Higher-quality pipes may include enhanced expenses, however they frequently use enhanced longevity and long life, which can warrant the financial investment with timeThe schedule of certain pipeline materials can vary substantially based on area and supplier relationships. Companies need to establish a trusted network of distributors to assure that they can source materials immediately and prevent project hold-ups.

Furthermore, fluctuations in market need and worldwide supply chain problems can impact both price and accessibility. As a result, it is essential for sectors to stay educated about market fads and preserve flexibility in their supply chain methods. Ultimately, a well-considered strategy to set you back and accessibility will certainly improve operational effectiveness and task success.

Making Sure Compliance and Safety Specifications

To browse these intricacies, firms should carry out thorough research study on suitable criteria such as ISO, ASTM, and ASME. Teaming up with suppliers that focus on compliance can streamline wikipedia reference the selection process, making sure that all pipeline supplies meet requisite accreditations. Routine audits and assessments additionally improve security by determining possible hazards or deficiencies in products. By focusing on conformity and security, companies not only discover here secure their labor force however likewise enhance their operational performance and online reputation within the sector. As a result, picking the appropriate pipeline supplies is a vital step in the direction of attaining a risk-free and certified functioning atmosphere.

Frequently Asked Inquiries

What Are the very best Brand Names for Pipeline Materials in My Sector?

Leading brands for pipeline products include PVC, Victaulic, and Mueller. Their track record for sturdiness, development, and considerable product ranges makes them preferred selections throughout various markets, making sure dependable efficiency and top quality in pipeline applications.

Just how Do I Keep Pipelines to Ensure Long Life?

To maintain pipes for longevity, regular assessments, cleansing, and correct securing are essential. In addition, staying clear of severe temperature levels and using protective coverings can avoid rust, eventually prolonging the life-span and efficiency of the piping system.What Tools Are Important for Pipe Installation?

Important tools for pipeline installment include pipe wrenches, cutters, fittings, a degree, gauging tape, and a welding torch. These tools assist in precise measurements, safe links, and general efficiency, ensuring an effective pipeline installation procedure.Can I Tailor Pipe Materials for Specific Projects?

Where Can I Discover Specialist Advice on Pipe Selection?

Professional investigate this site recommendations on pipe choice can usually be located through industry-specific forums, producer agents, and expert trade associations. Furthermore, specialized web sites and regional suppliers frequently provide examinations to assist guide finest choices for particular projects.When selecting pipe products for numerous applications, recognizing the distinctions among pipe products is essential. Picking the ideal size and specifications for pipe products is crucial for ensuring suitable performance in any application. Just how can one assure that pipe products fulfill the certain demands of an application? Ensuring conformity with guidelines and safety criteria is vital in the choice of pipeline supplies for various applications. Crucial tools for pipe setup include pipeline wrenches, cutters, fittings, a degree, determining tape, and a soldering iron.

Report this wiki page